Manufacturing

ITE manufactures a diverse range of refractory products for the major industrial end-users of the region. The plant has advanced product lines for the manufacture of refractory blocks, monolithic masses, and precast shapes. These products support the needs of the ferrous, non-ferrous, petrochemical, cement and other industrial processes of the region.

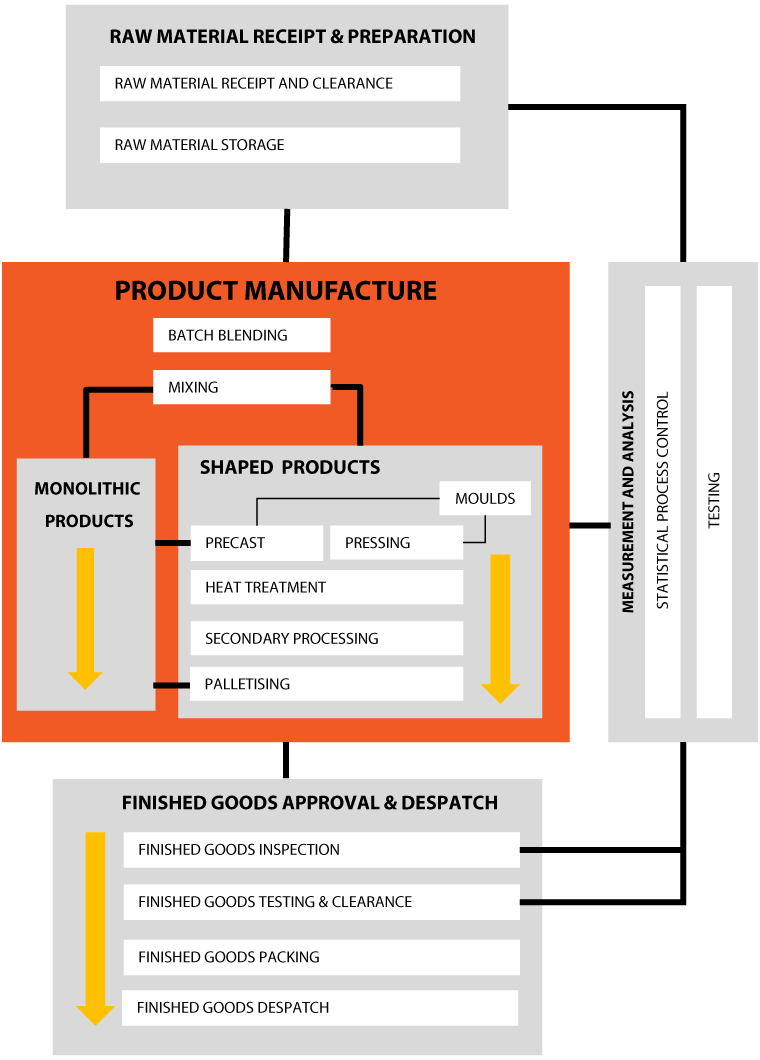

Refractory manufacturing involves 6 key processes:

- Raw material approval

- Batching of raw materials

- Mixing

- Forming

- Heat treatment

- Final processing

Quality verification checks are conducted throughout the process to ensure compliance with finished goods tolerances and stated customer requirements.

Our mission being to build up lasting business relationships with customers by providing quality products delivered on time, that provide market leading value in use to our valued customer base.

ITE has a well-equipped laboratory enabling us to adhere to international ISO / DIN test standards – from receipt of raw materials right through to testing and release of finished goods, and if required can provide testing services to other interested parties of the region.